Ensure Your Products Perform as Expected With Analysis Capabilities From Saratech

Get Started With a Quote

Our CAE Services Capabilities

We provide a wide range of analysis capabilities, from being your full-time services provider to doing occasional, one-off analysis for you, and from training your analysis team to improve their skills to improving your team’s analysis processes in order for them to increase overall process throughput.

CAE Services: Analysis Types

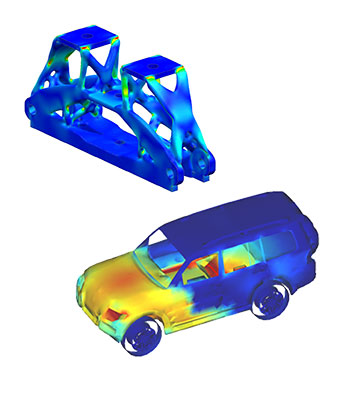

Saratech has extensive expertise in running analyses to ensure that your products perform as expected, across a wide variety of operating conditions and across a wide variety of product materials (linear and nonlinear, metals, plastics, and laminates). These analysis capabilities include:

- Static analysis (linear and nonlinear) for stress, strength, and deformation

- Dynamic analysis for modal analysis and for vibration response due to harmonic and transient loads

- Buckling analysis for structural stability

- Fatigue and fracture mechanics for crack growth, crack propagation, and structural life

- Thermal analysis for heat transfer (conduction, convection, radiation)

- Flow analysis for air and fluid flow in and around structures

- Cooling of electronic systems (combined thermal-flow)

- Kinematics and multibody dynamics for assembly motion and mechatronic simulation

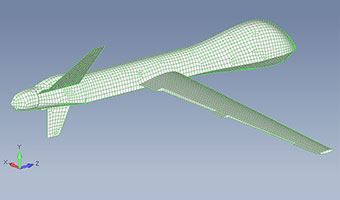

- Aeroelasticity analysis for structural-aerodynamic interaction of airborne structures

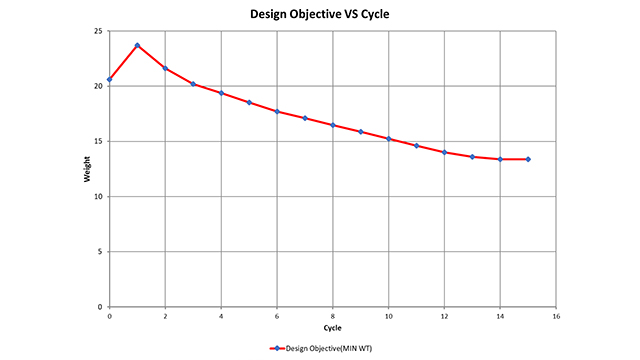

Design Optimization With Saratech’s CAE Services

Once you have ensured that your product will perform as intended, how can you make it better? You could undertake a manual design improvement approach, in which you make design changes and assess their results, or you can use design optimization software to do this for you. Saratech offers such in-software solutions to optimize a part or assembly to improve your design and/or to reach your design objective. We have experience in using Simcenter to improve your designs (minimize weight, maximize stiffness, minimize deformation, and more), taking into account the design requirements and design and manufacturing constraints.

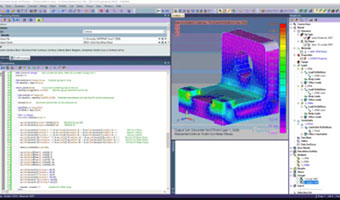

Process Automation

Our CAE services include analysis process automation which is about encapsulating analysis workflows in the software in order to automate repetitive analysis tasks, providing a faster, more reliable analysis process. We have experience in creating NX, Simcenter, and Femap APIs in order to provide analysis automation for:

- Creating functions for time consuming manual tasks

- Custom report generation and quality check protocols

- Custom visualization and non-native data transfer methods

Analysis Training

Are your analysis team’s capabilities where they need to be? Saratech’s CAE engineering services can help increase their skills by providing training in the areas above (analysis types, design optimization, and process automation) for Simcenter and Femap. This training can be provided online or in person. We also provide a software skills assessment for you and your team to determine analysis capabilities needing enhancement.

Analysis Process Improvement

Our CAE services can help your analysis team define and implement improved analysis processes to improve process throughput and to better verify that your products meet their requirements. We offer several types of process improvement capabilities, including:

Why Choose Saratech For Your CAE Services?

Experienced Analysis Team

Our CAE engineering team understands the applications of analysis, as we have experts in many analysis disciplines and have experience in running many types of analysis software products

All-In-One Analysis Partner

Our broad experience—from running different analysis types to providing training to assessing and improving your analysis processes—gives you one company to partner with for all of your analysis needs

Key to Your Product Development Process

Saratech’s CAE service team understands the overall product development process and understands where/how analysis fits in and helps make your products better

Resources

Whitepaper: What to Look for in Your Service Provider Read the following whitepaper to gain critical insight into what to look for in your service provider.

Whitepaper: Improving Your Company's Simulation Capabilities and Processes for Business BenefitThe following whitepaper introduces a general framework used to address the top simulation issues companies experience.